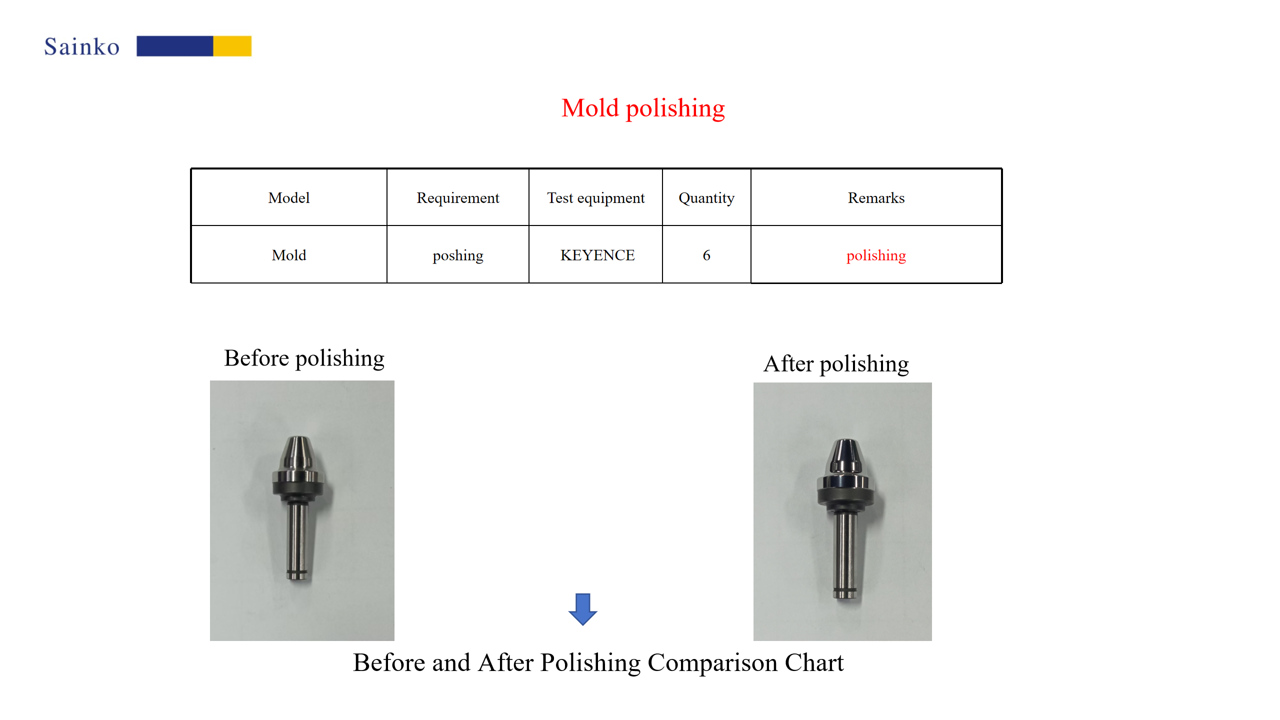

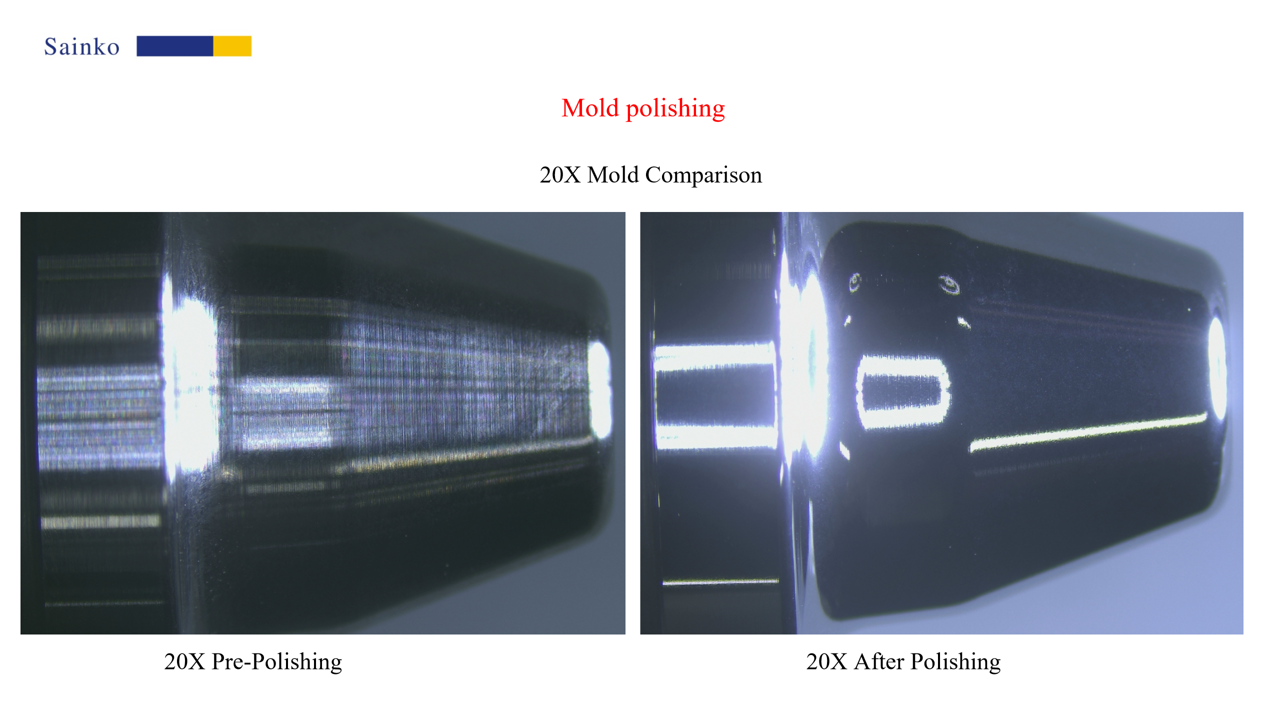

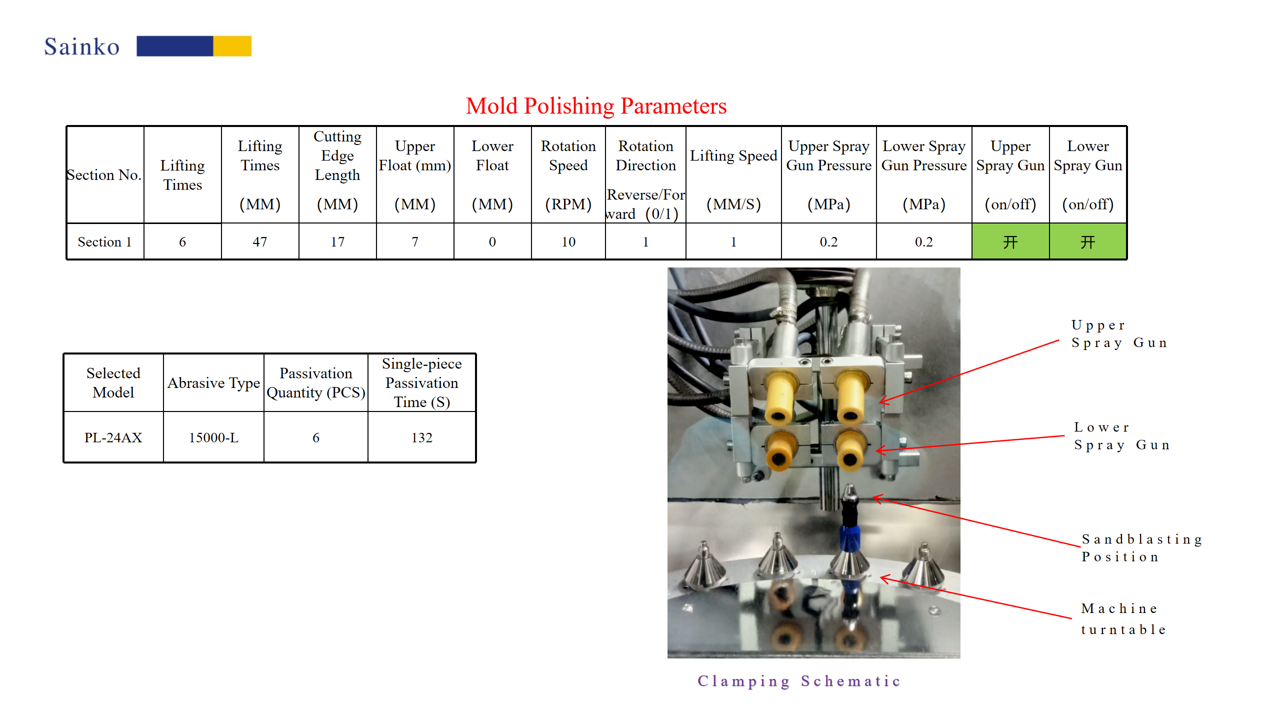

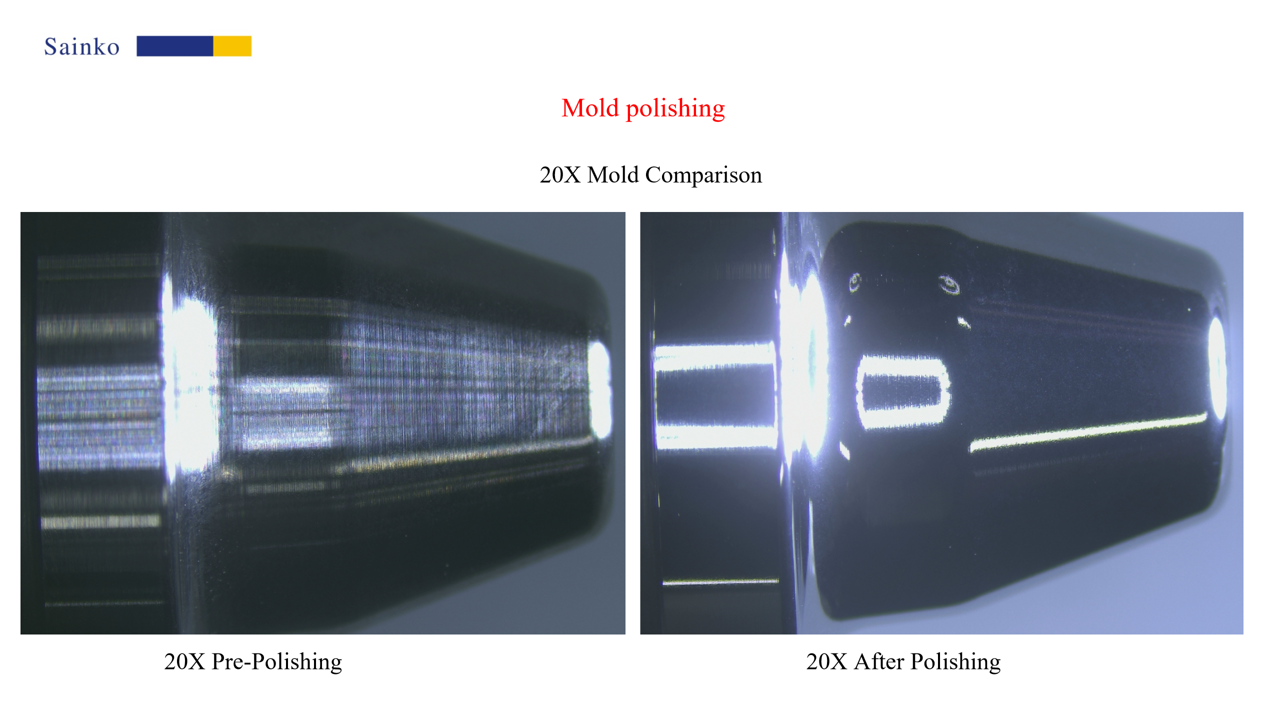

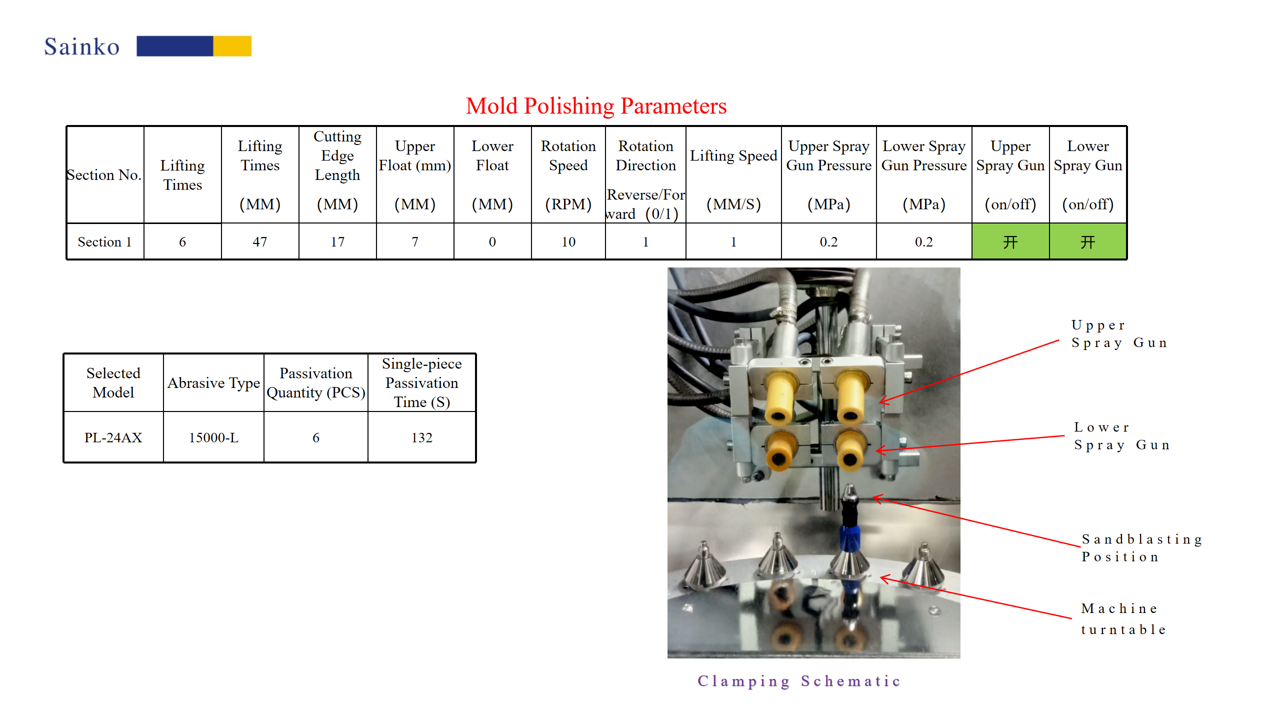

This mold polishing is carried out for 6 molds, using Keyence as the testing equipment, PL-24AX equipment and 15000-L abrasive to implement a one-stage process (6 lifting times, blade length of 47/17mm, upper floating 7mm/lower floating 0mm, rotation speed of 10RPM, lifting speed of 1mm/s, dual spray gun pressure of 0.2MPa opening), with a single passivation time of 132 seconds; During polishing, the mold is fixed to the machine turntable through a tool holder, and the sandblasting position corresponds to the upper and lower spray gun areas; In terms of effect, the surface of the mold has fine patterns and low glossiness before polishing. After polishing, it presents a mirror effect. At a magnification of 20 times, the processing texture disappears before polishing, and the surface is smooth and polished.

2026-01-16

2026-01-16